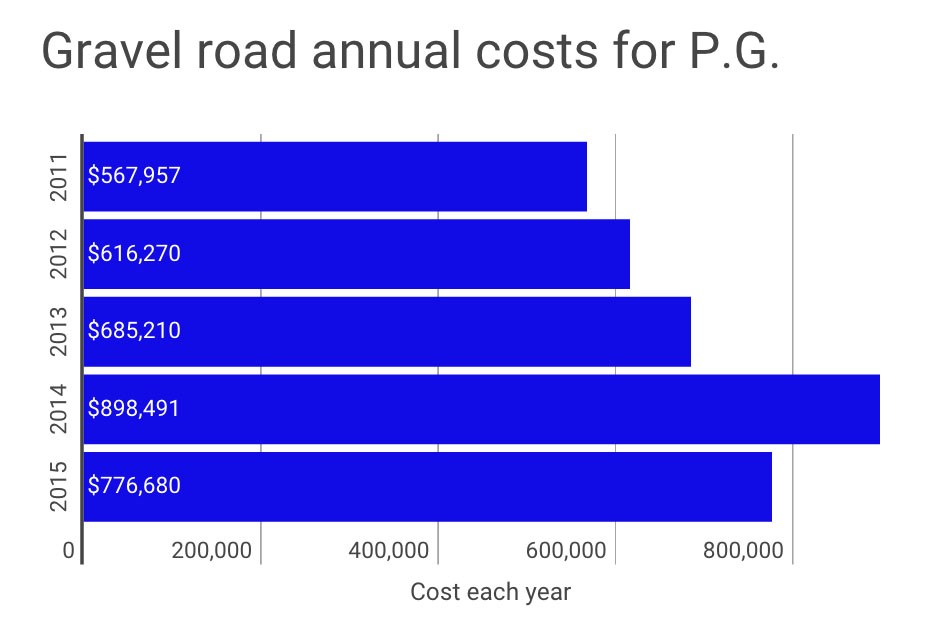

The city cut its gravel road maintenance costs last year by more than $120,000.

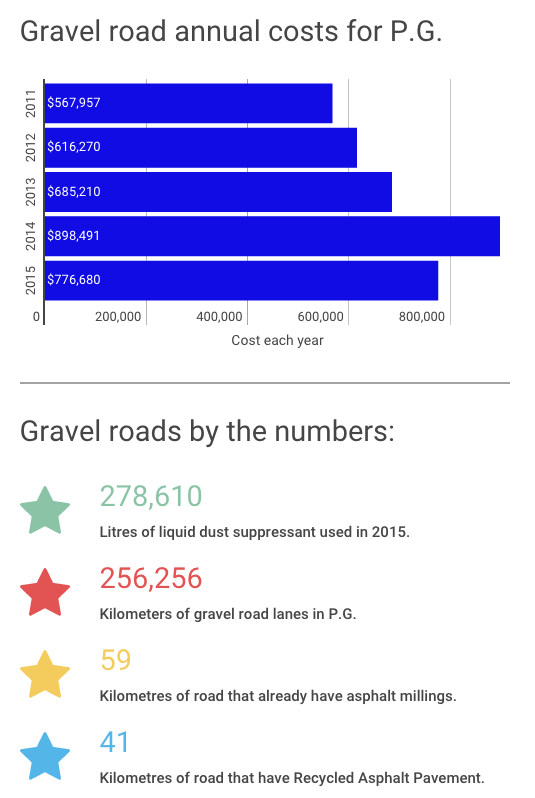

It scaled back from 2014’s four-year high of $898,491 in spending to $776,680. At that cost, workers cleaned about 256 kilometres of lanes throughout the city, according to a Gravel Road Maintenance Program report to city council.

That said, 2015 spending was still higher than 2011 to 2013 by more than $90,000 each year.

The report said the city’s current approach to gravel roads should be considered short-term solutions. Currently it does grading and applies a dust control product, but the report said council should consider milling and recycled asphalt pavement as long-term approaches to dusty roads

“A reduction in the gravel roads inventory would improve air quality and reduce maintenance activities,” said the report, authored by Dave Dyer, general manager of engineering and public works.

Urban alleyways are suited for hot mix asphalt paving while rural gravel roads require milling and recycled asphalt pavement.

Because of the weight of grading equipment, city workers don’t start with gravel roads until the spring when vehicle weight restrictions are removed by the Ministry of Transportation and Infrastructure.

In most cases roads will have been seen by city crews twice a year – once in early summer and again in late summer. After each, staff apply dust control products.

“Typical maintenance includes grading of the travel surface, dust control, shoulder vegetation control, culvert maintenance and ditch cleaning,” the report noted.

The surface quality of gravel roads are degraded by spring thaw and precipitation as well as local traffic, the report said. Over time the crushed gravel become loose and then airborne, creating the need for dust control.

Over two weeks in 2015, Tiger Calcium was contracted out and applied 278,610 litres of the liquid dust-suppressant agent, made of calcium chloride and water, on gravel roads.

But the less this method is used, the better. The report recommended “mill and fill” paving process as one solution for roads with minimal traffic.

With this approach, roads would still resemble gravel, but change over time because of the millings makeup.

“With warm weather, traffic and the annual aging process, the millings can visibly turn into a product that resembles pavement,” said the report, noting this approach is best suited for roads with low vehicle volume.

So far the city has used asphalt millings on 59 lane kilometres of gravel roads within the city’s inventory.

Since 2004, the city has recovered slabs and chunks of asphalt from job sites, known as recycled asphalt pavement or RAP.

Crews crush the stockpiled material and add a bit of crushed gravel. Then it’s applied to roads at a minimum of 150 millimetres in thickness.

Gravel roads outside of Prince George are managed by the Ministry of Transportation and Infrastructure. They use “seal coating” or “chip seal” on their roads, which can be good for seven to 10 years. The report doesn’t say how long mill and fill or RAP roads last.

Correction: A previous version of this article said gravel roads outside of Prince George are managed by both the Ministry of Transportation and Infrastructure and Regional District of Fraser Fort George when the roads are entirely the Ministry's responsibility.