A bridge built by a Prince George company is the first to cross Canada's mightiest river.

Ruskin Construction is behind the Mackenzie River crossing, directly linking Yellowknife to the rest of Canada and making the ferry crossing in the summer and the ice road connection in the winter unnecessary.

The NWT government first legislated their desire for a historic first bridge over the Mackenzie in 2002. The initial price estimations were vague, but some were as low as $50 million.

The final price was slightly over $200 million, but the long journey is at an end. To get there, the territorial government of the day had to sacrifice from other programs and projects, go to the federal government for loans, scrap the initial designs and start again, collapse the initial holding corporation, and take the entire project into direct government hands.

One of the casualties was the first primary contractor, Adcon Construction of New Brunswick. In financially bloody fashion, that company bowed out, leaving the NWT government to pick someone else to complete what had hardly begun.

At the time, one of the project's main subcontractors, Ruskin Construction, was already involved at the chosen crossing at Fort Providence. A veteran bridge building company, Ruskin just completed one over the Red River in Manitoba and they are subcontractors on the Port Mann Bridge effort - but this was a megaproject by anyone's standards. It was 2010 when the new directions had to be taken, and Ruskin was promoted to primary contractor to get the bridge back on course.

"They became involved in a big way. The Atcon event caused us a year's delay, and the initial price tag at that point was $162 million but we are at $202 million today. That is a big overrun," said NWT Minister of Transportation David Ramsay. "There were some trials and tribulations, but we are going to get a finished product, and it is a testament to both sides. Ruskin was willing to work with us and I would be comfortable working with Ruskin again."

The work itself was anything but comfortable. Yet after four long years, the Deh Cho Bridge (it's the Dene name for the Mackenzie; it means "big river") was ready for its ribbon cutting Friday.

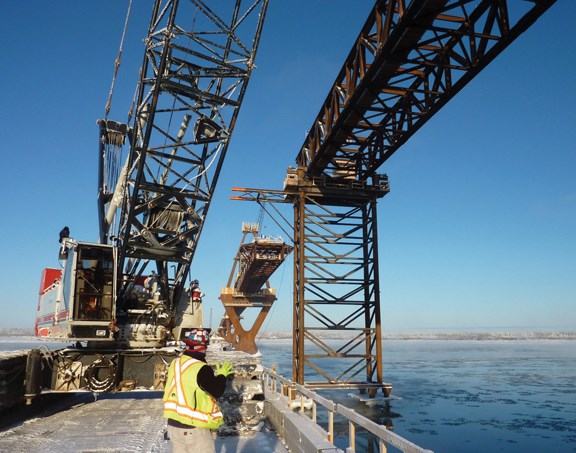

"The coldest recorded temperature was minus-59," project manager Corey Ross said. Half the year was also spent essentially in the Arctic dark. "And we were always watching the clock in the spring for the ice to let go. We built a temporary bridge alongside the main structure, and staged from the temporary deck, moving along as you go. We had to get that temporary bridge out of the water before the iceflows each year, or the whole thing would be destroyed. We were always racing the river. If you lost a season, you lost the whole year."

The release of Mackenzie River's ice is one of the great wonders of Canada's natural world. Millions of tonnes of ice, much of it more than six feet thick, suddenly barrels down the channel. It grinds to dust anything in its path. The eight piers standing like space-age inukshuks in the water had to be designed to hold the weight of the steel and concrete above, but also to withstand this annual onslaught.

As brutish as the piers had to be, the engineering and construction involved was calculated to the micro-detail. The span is more than a kilometre across. A crew on each shore worked across the river towards each other. When they arrived at the middle, there was less than six millimetres of compensation required.

"We did a midair connection in the middle of winter," said Ross. "There were so many challenges to this project."

Some of the challenges were indicative of why the Deh Cho Bridge was needed in the first place. Ruskin had to move about 7.7 million pounds of steel to the site. Most of it went by rail to Hay River, then onto trucks for the 170 remaining kilometres to Fort Providence. To get the steel to the north side of the river required using the small Merv Hardie ferry in summer or trucks hauling across ice roads in the winter. In spring there are times when the ice is too thin to drive on yet the ferry is unable to ply the waters. The only way across, then, was by aircraft.

"We encountered gas shortages just before the ice lets go," said Ross. "Once, we needed fuel badly and it took us three or four hours to locate any in Yellowknife. It's a fuel shortage every spring, for everyone up there, so that issue should be eliminated."

Companies are already expressing plans to locate on the north side now, especially in the capital city of Yellowknife, due to the certainty the bridge provides.

"It really does usher in a new way of doing business in the north Slave area. Companies won't have to stockpile goods, you can reliably move goods," said Ramsay. "Any transportation-related costs were passed on to the consumer."

There was also a major inconvenience each year to students attending university or college. If they couldn't get their vehicles over due to road conditions, they would have to park in Hay River and helicopter to school in Yellowknife, then get back to Hay River to retrieve their vehicles days or weeks later when the ice let go and it was safe for the ferry again.

The costs of the bridge project will be made up in the savings of no longer operating the Merv Hardie, and through a toll for commercial traffic (some critics warn this may keep consumer prices high on the north side of the river). Regular vehicles will pay nothing, but rigs will pay one-way-only fares depending on how many axles they have (for example, a B-train fare is $275 but a two-axle truck fare is $75).

"The public has had just about enough of talking about it," said Ramsay. "There were numerous issues during the life of the construction of the bridge, but now we all just want to get it open and get on with the benefits it will bring. We will do a complete post-mortem on the process, to learn from the mistakes and take all the lessons we can because we will have more capital infrastructure in the future."

Ruskin, too, will have many more projects on which to apply the Deh Cho lessons. So rare was this bridge that international interest has already come to them as a result. Ross went to Chicago in June to present the technical details to the annual convention of the Piledrivers, Divers, Bridge, Dock and Wharf Builders Union that supplied much of the labour.

"It has put us on the map," said Ruskin's company president Jim Basha. "We are already getting calls because of this project."

The fascination is in Ruskin's choices of state-of-the-art materials and inventive uses in construction. The Eiffel Tower in Paris is 320 metres tall, less than one third the length of the Deh Cho Bridge. Yet the tower needed 7,000 tonnes of steel while the bridge needed only about 4,000 tonnes of steel. The superstructure's total weight (concrete, asphalt, cables, etc.) is about 14,000 tonnes. How is it possible to be so light, yet stand up to traffic, weather torture, and time?

A lightweight truss system Ruskin put to use cut down the use of structural steel by 25 per cent, and designing the deck system as a four-way slab cut down the concrete mass by 30 per cent while also eliminating the need for pre-stressing.

"However, these innovative design features only amplified the constructability challenges to be met by Ruskin," said Ross. "Standard construction methodologies had to be analyzed and customized to meet the demands of this bridge."

The company stated that the design pays special attention to long-term durability, corrosion protection, and provides easy access for inspection and maintenance, with the ultimate goal of keeping the life-cycle cost of the bridge to a minimum.

"It was the largest infrastructure project ever undertaken in the Northwest Territories. It's a very special piece of engineering," Basha said. "It needed about 700,000 person-hours of labour, and we didn't have a single serious injury or a single environmental issue."

The Ruskin crews were not alone in the endeavour. The building of the Deh Cho Bridge involved major industrial input from Quebec, New Brunswick, Alberta, Switzerland, the U.S. and England, but, said Basha, "1,400 truckloads of all sorts of materials came out of Prince George alone, and a lot of the people who worked there were from Prince George, so just imagine the impact on our local economy."

Mackenzie River sidebar

At 4,241 kilometres in length, the Mackenzie-Peace-Finlay river system is the 13th longest in the world and the longest single waterway of Canada. The only other river system on the continent longer than the Mackenzie is Mississippi-Missouri river system.

The Mackenzie's total watershed covers an estimated 1.8 million square kilometres, forming the western hub for much of Canada's earliest economic activities by trappers, prospectors and explorers. The economic pulse of the British and French empires was affected by the seasonal ebbs and flows of the Mackenzie.

Tracing the tributaries of the Mackenzie backwards reaches Jasper at its southern tip, the Black Lake area of Saskatchewan at its eastern edge, and the Omineca Mountains of British Columbia to the west.

Among the many lakes that feed into the Mackenzie - Great Bear (the eighth largest in the world), Great Slave (the 10th largest in the world), Athabaska, Cree, and Lesser Slave - is Williston Lake and the bodies of water north and east of the continental divide at Summit Lake between the Pacific and Arctic Oceans.